What is interwoven fabric made of?

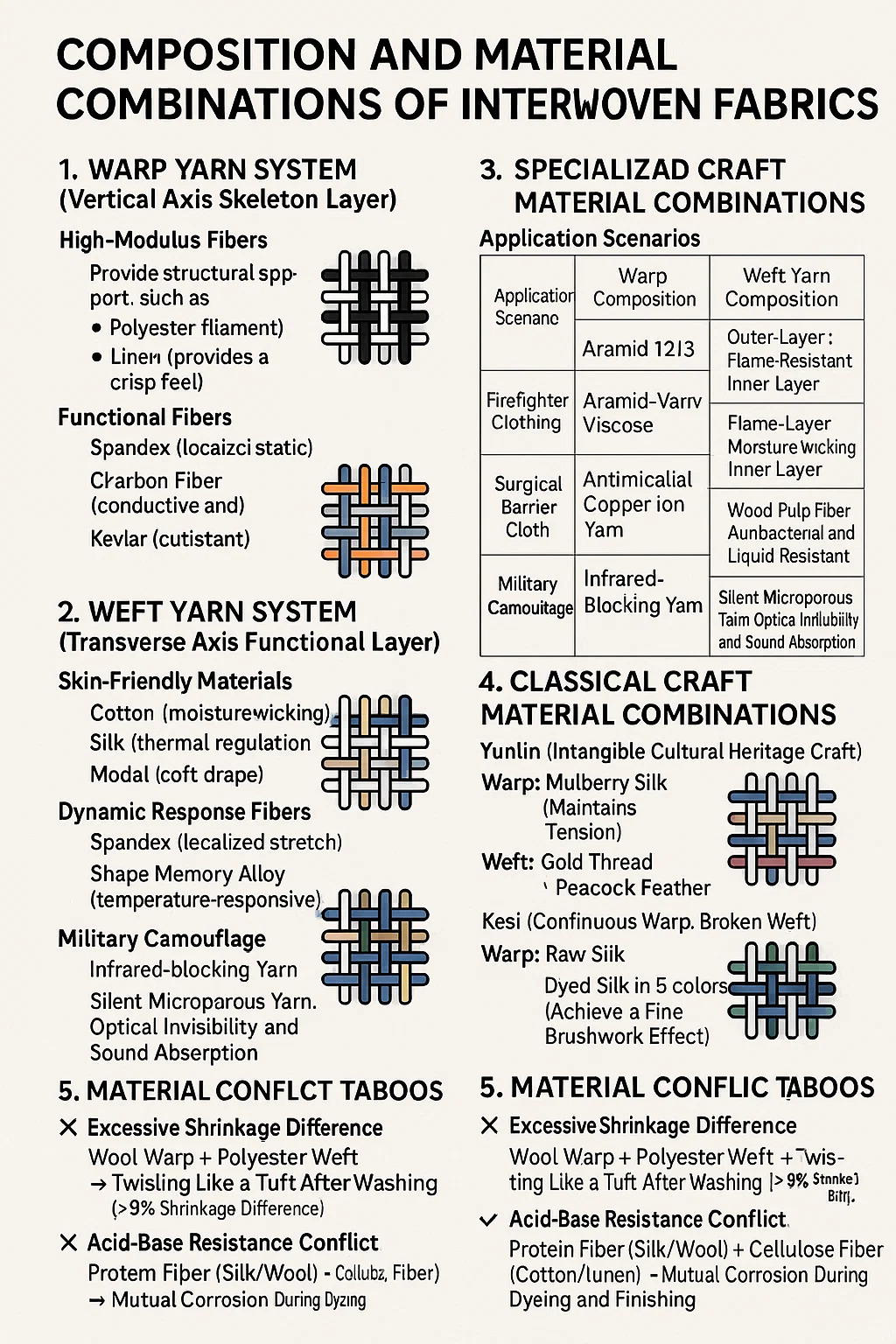

Composition and Material Combinations of Interwoven Fabrics

1. Warp Yarn System (Vertical Axis Skeleton Layer)

High-Modulus Fibers: Provide structural support, such as polyester filament (resistance to stretching), linen (provides a crisp feel)

Functional Fibers: Metal Wire (anti-static), Carbon Fiber (conductive and heat-generating), Kevlar (cut-resistant)

2. Weft Yarn System (Transverse Axis Functional Layer)

Skin-Friendly Materials: Cotton (moisture-wicking), Silk (thermal regulation), Modal (soft drape)

Dynamic Response Fibers: Spandex (localized stretch), Shape Memory Alloy (temperature-responsive)

3. Specialized Interwoven Combinations

| Application | Warp Composition | Weft Composition | Performance Synergy |

| Firefighting Gear | Aramid 1313 | Flame-retardant Viscose | Thermal barrier + Sweat management |

| Surgical Barrier | Antibacterial Copper-ion Yarn | Wood-pulp Fiber | Pathogen suppression + Fluid blocking |

| Military Camouflage | IR-attenuating Polymer Threads | Sound-dampening Micro-perforated Yarn | Multi-spectral cloaking + Acoustic absorption |

| Aerospace Seat Covers | Carbon Fiber Tow | Phase-change Microencapsulated Cotton | Impact resistance + Thermal regulation |

| Arctic Exploration | Hollow Core Polar Fleece | Metalized Reflective Fiber | Core insulation + Radiant heat retention |

4. Classical Craft Material Combinations

Yunjin (Intangible Cultural Heritage Craft): Warp: Mulberry Silk (Maintains Tension) | Weft: Gold Thread + Peacock Feather (Three-Dimensional Color Development)

Kesi (Continuous Warp, Broken Weft): Warp: Raw Silk | Weft: Dyed Silk in Five Colors (Achieve a Fine Brushwork Effect)

5. Material Conflict Taboos

Excessive Shrinkage Difference: Wool Warp + Polyester Weft → Twisting Like a Tuft After Washing (>8% Shrinkage Difference)

Acid-Base Resistance Conflict: Protein Fiber (Silk/Wool) + Cellulose Fiber (Cotton/Linen) → Mutual Corrosion During Dyeing and Finishing

Golden Compatibility Rule: Warp Melting Point ≥ Weft Melting Point + 50°C (To Avoid Melt-Stick Effect During Finishing)

English

English

PREV

PREV