How to choose interwoven fabric?

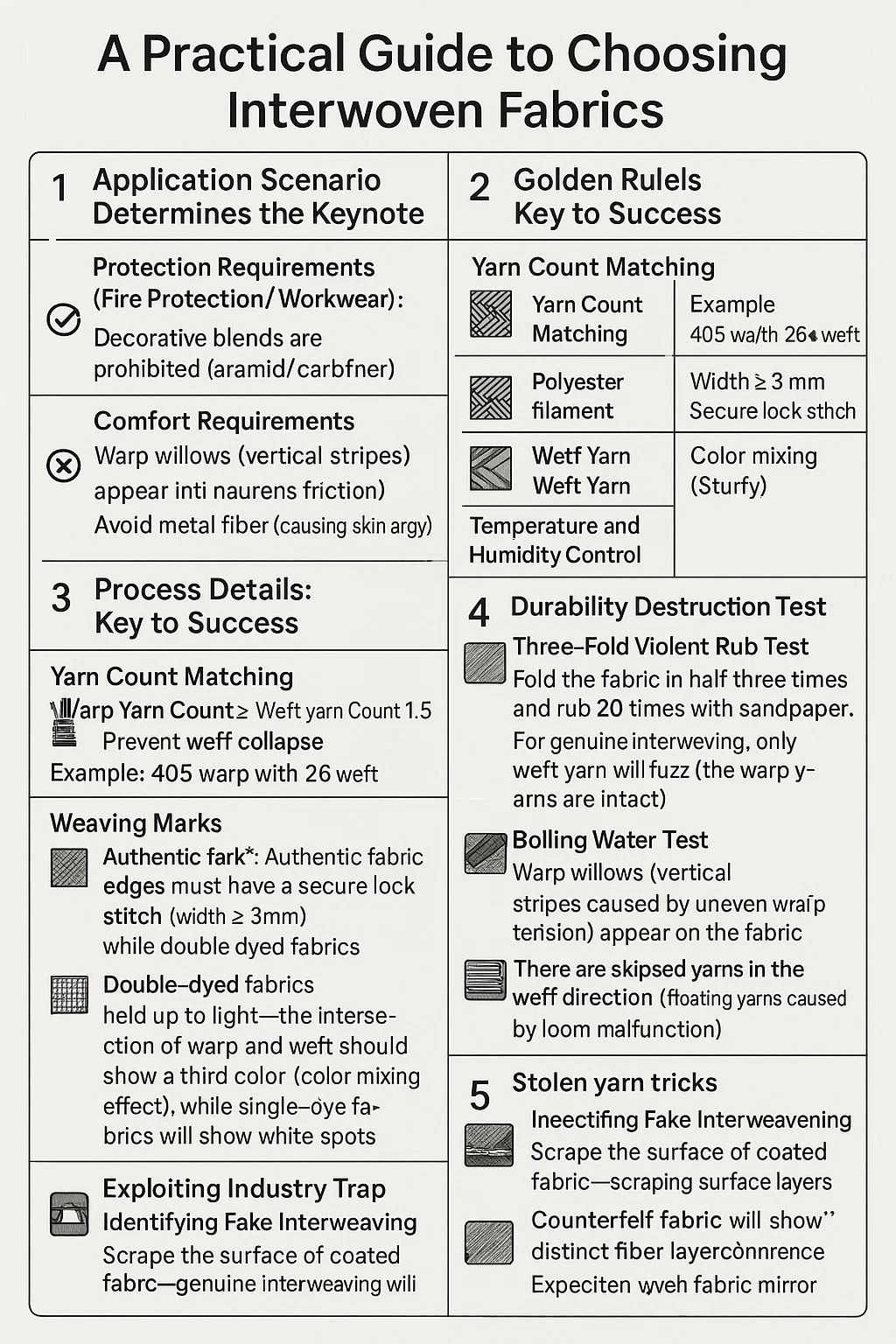

A Practical Guide to Choosing Interwoven Fabrics

1. Application Scenario Determines the Keynote

Protection Requirements (Fire Protection/Workwear): Warp yarns must be high-strength fibers (aramid/carbon fiber). Decorative blends are prohibited (reduced protection level).

Comfort Requirements (Underwear/Bedding): Weft yarns must be natural materials (long-staple cotton/silk). Avoid metal fibers (causing skin allergies due to friction).

2. Golden Rules for Warp and Weft Combinations

| Performance Target | Warp Selection | Weft Selection | Core Lockout |

|---|---|---|---|

| Wrinkle Resistance | Polyester Filament | Liquid Ammonia-Finished Cotton | Wool warp + Linen weft Post-wash distortion |

| Two-Way Stretch | Core-Spun Spandex | Nylon Elastic Yarn | Pure Cotton Warp Seam rupture risk |

| Thermo-Hygroscopic | Phase-Change Fibers | Modal | Synthetic-Dual Layers Thermal choking |

| Structural Integrity | High-Tenacity Viscose | Carbonized Bamboo | Silk Warp + Rubber Weft Degrades in humidity |

| Flame Retardancy | Oxidized PAN Fibers | Mineral-Coated Rayon | PVC-Blended Warp Toxic fumes when burned |

3. Process Details: Key to Success

Yarn Count Matching: Warp Yarn Count ≥ Weft Yarn Count × 1.5 (Prevents weft collapse). Example: 40S warp with 26S weft

Weaving Marks: Authenticity Mark: Authentic fabric edges must have a secure lock stitch (width ≥ 3mm), while counterfeit fabrics have ordinary heat-cut edges.

Dyeing and Finishing Verification: Double-dyed fabrics should be held up to light—the intersection of warp and weft should show a third color (color mixing effect), while single-dye fabrics will show white spots.

4. Durability Destruction Test

Three-Fold Violent Rub Test: Fold the fabric in half three times and rub it 20 times with sandpaper. For genuine interweaving, only the weft yarn will fuzz (the warp yarns are intact).

Boiling Water Test: Boil in water for 5 minutes and remove. High-quality fabrics will show a warp and weft shrinkage difference of ≤3% (low-quality fabrics will curl and deform).

UV Aging: Expose to sunlight for 48 hours. Warp yarn strength of UV-treated fabrics will decrease by <10%.

5. Exploiting Industry Trap

Identifying Fake Interweaving: Scrape the surface of the coated fabric—genuine interweaving will show distinct fiber layers after scraping, while counterfeit fabrics will show the base fabric.

Defective Product Characteristics: Warp willows (vertical stripes caused by uneven warp tension) appear on the fabric. There are skipped yarns in the weft direction (floating yarns caused by loom malfunction).

Stolen yarn tricks: Unscrupulous vendors reduce the warp yarn density (e.g., nominally 120 threads/inch, but measured at <100 threads/inch). This requires counting with a fabric mirror.

English

English

PREV

PREV