How many types of woven fabric are there?

Content

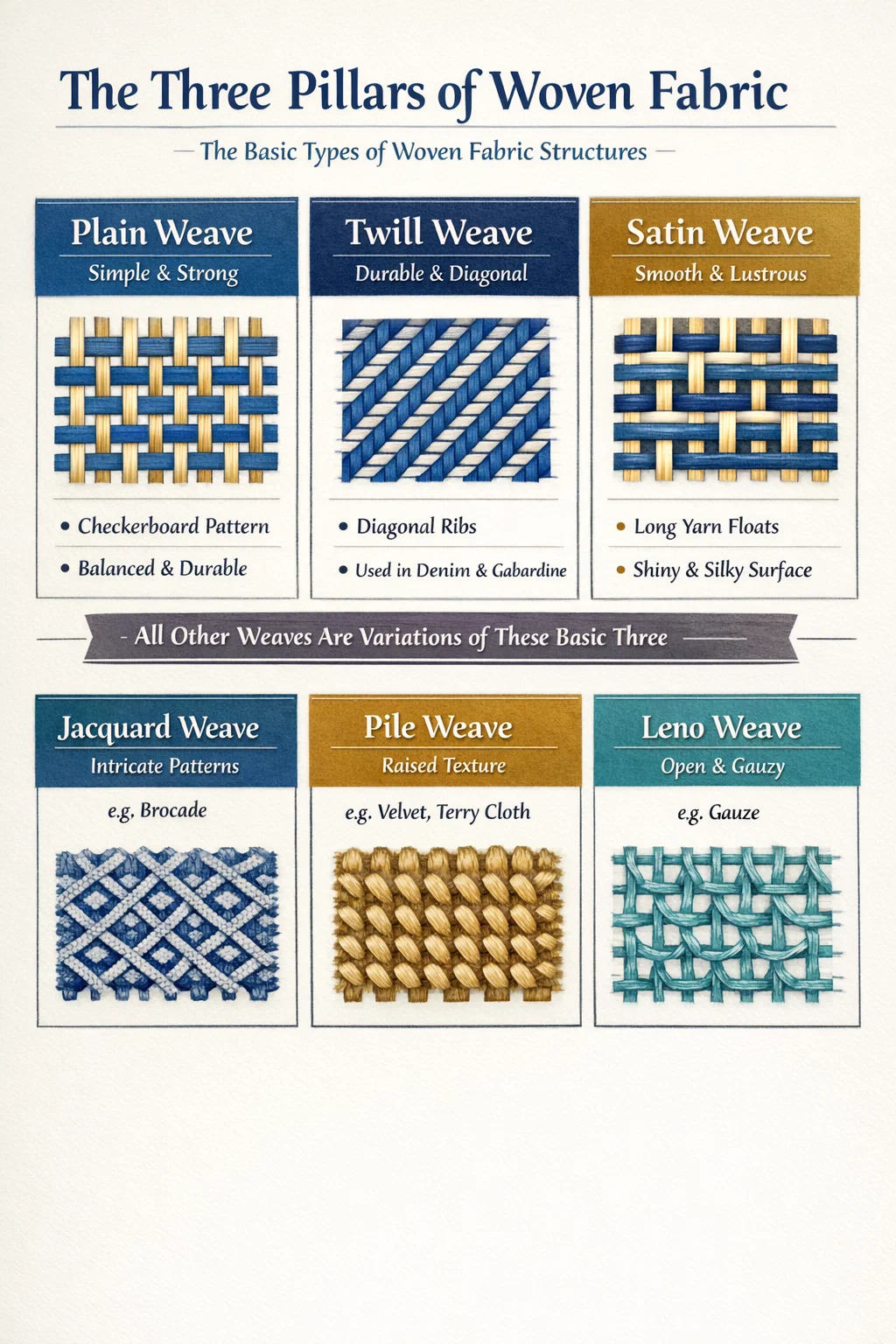

Direct Answer: The Three Pillars of Woven Fabric

While there are hundreds of specific market names for textiles, there are technically three fundamental types of woven fabric structures from which almost all others are derived: Plain weave, Twill weave, and Satin weave. Every other variation, such as Jacquard, Dobby, or Pile weaves, is a complex modification of these three basic interlacing patterns. Understanding these categories is essential for identifying the durability, drape, and utility of any textile product.

The Plain Weave: The Most Common Woven Fabric

The plain weave is the simplest and most resilient form of weaving. In this structure, the warp (vertical) and weft (horizontal) threads cross over and under each other in a simple alternating pattern. This creates a checkerboard-like interlacing that is identical on both sides.

ShutterstockSub-types of Plain Weave

Even within the "plain" category, variations exist based on yarn thickness and grouping:

- Basket Weave: Two or more warp threads interlace with two or more weft threads, creating a porous, decorative look seen in Oxford shirts.

- Rib Weave: Either the warp or weft yarn is heavier or grouped together, creating a raised ridge or "rib" in the woven fabric, such as in Poplin or Grosgrain.

Common examples of plain woven fabric include Chiffon, Organza, Canvas, and Percale. Because the threads interlace frequently, these fabrics are highly stable and do not unravel as easily as more complex weaves.

The Twill Weave: Durability and Diagonal Patterns

Twill is a type of woven fabric characterized by diagonal ribs or lines on its surface. This is achieved by passing the weft thread over one or more warp threads and then under two or more warp threads, with a "step" or offset between rows.

This structure allows for a higher thread count than plain weave, making the fabric thicker and more opaque. Because there are fewer interlacing points, a twill woven fabric drapes better and resists wrinkles more effectively than plain weaves.

| Fabric Name | Weave Type | Key Characteristics |

|---|---|---|

| Denim | Twill | Extremely durable, diagonal ribs |

| Gabardine | Twill | Water-resistant, steep diagonal |

| Herringbone | Broken Twill | Zig-zag pattern, used in suits |

The Satin Weave: Smoothness and Luster

Satin weave is the most complex of the basic three. It is designed to maximize the "float" of the yarn—where a thread travels across several perpendicular threads before interlacing. This creates a surface that is exceptionally smooth, lustrous, and reflects light beautifully.

If the fabric uses filament fibers like silk or polyester, it is called Satin. If it uses short-staple yarns like cotton, it is called Sateen. While visually stunning, this type of woven fabric is more prone to snagging because the long floats can easily catch on sharp objects.

Complex and Decorative Woven Fabric Varieties

Beyond the basics, industrial weaving technology allows for the creation of intricate patterns and multi-layered textiles. These are often categorized separately because they require specialized looms.

Jacquard Weaves

A Jacquard loom controls individual warp threads, allowing for highly complex, multi-colored patterns to be integrated directly into the woven fabric. This is not a print; the pattern is the structure. Examples include Brocade and Damask.

Pile Weaves

Pile weaving involves adding a third set of yarns that stand up from the base fabric. These loops are often cut to create a soft, "fuzzy" texture. Common pile fabrics include Velvet, Corduroy, and Terry Cloth (used for towels).

Leno Weave

Leno is a specialized woven fabric where warp threads twist around each other as they interlace with the weft. This locks the threads in place, making it possible to create very loose, "open" fabrics like gauze and mosquito netting without the threads shifting or bunching together.

Technical Considerations in Woven Fabric Production

The final identity of a woven fabric isn't just about the weave type; it's also about thread density and yarn count. For instance, a plain weave cotton can be a translucent Voile or a heavy-duty Canvas depending solely on the thickness of the yarns used during weaving.

Industrial textiles often use a "Thread Count" metric to measure quality. In a high-quality woven fabric, a higher count of threads per square inch typically results in a smoother, more durable surface. However, the weave type dictates the limit; you can pack many more threads into a Satin weave than a Plain weave because the floating threads occupy less vertical space at the interlacing points.

English

English

PREV

PREV