What is shiny stretch fabric called?

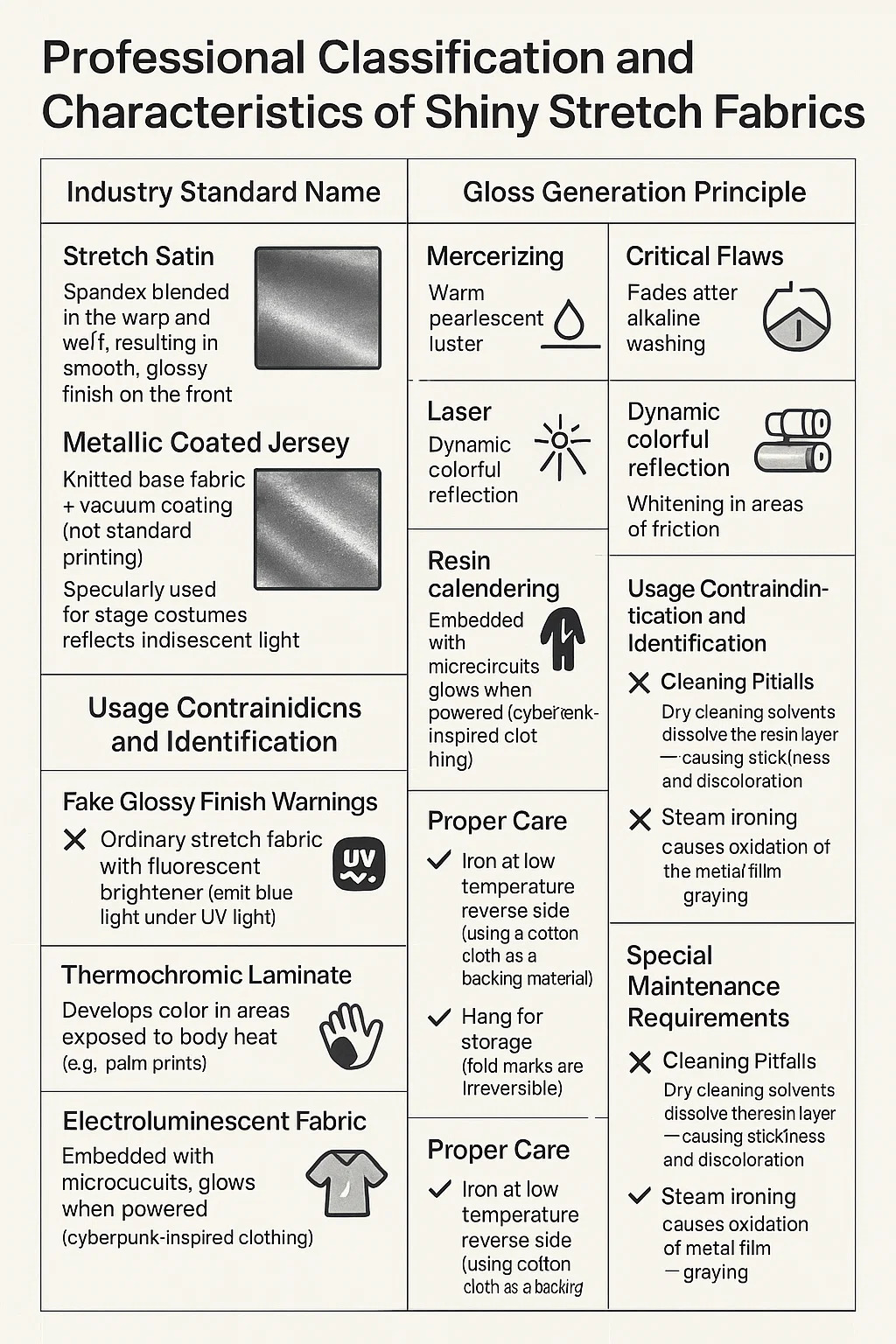

Professional Classification and Characteristics of Shiny Stretch Fabrics

1. Industry Standard Name

Stretch Satin

Spandex blended in the warp and weft, resulting in a smooth, glossy finish on the front

Commonly used for the hemming of evening gowns and cheongsams

Metallic Coated Jersey

Knitted base fabric + vacuum coating (not standard printing)

Specularly used for stage costumes, reflects iridescent light when bent

2. Gloss Generation Principle

| Technique | Visual Effect | Risk Factors |

| Mercerization | Pearl-like luster with depth | Loses sheen after alkaline cleaning |

| Laser Etching | Dynamic rainbow refraction | Abraded areas turn chalky white |

| Resin Calendering | Mirror reflection finish | Cracks above 60°C |

| Vacuum Metallization | True metallic chrome effect | Peels at fold lines |

| Crystalline Coating | Diamond micro-sparkle | Cloudiness when humid |

3. Functional Variations

Photoluminescent Knit: Self-luminesces after absorbing UV light, used for marking dark areas of security uniforms

Thermochromic Laminate: Develops color in areas exposed to body heat (e.g., palm prints)

Electroluminescent Fabric: Embedded with microcircuits, glows when powered (cyberpunk-inspired clothing)

4. Usage Contraindications and Identification

Fake Glossy Finish Warnings: Ordinary stretch fabric with fluorescent brightener (emit blue light under UV light) Low-quality PVC coating (leaves permanent white marks when folded)

Authenticity Verification Methods: Lightly scratch with a fingernail leaves no marks (high-density scratch-resistant layer) No refractive error when rubbed and unfolded (uniform coating)

5. Special Maintenance Requirements

Cleaning Pitfalls: Dry cleaning solvents dissolve the resin layer → causing stickiness and discoloration Steam ironing causes oxidation of the metal film → graying

Proper Care: Iron at low temperature, reverse side (using a cotton cloth as a backing material) Hang for storage (fold marks are irreversible)

English

English

PREV

PREV