How is waterproof fabric made?

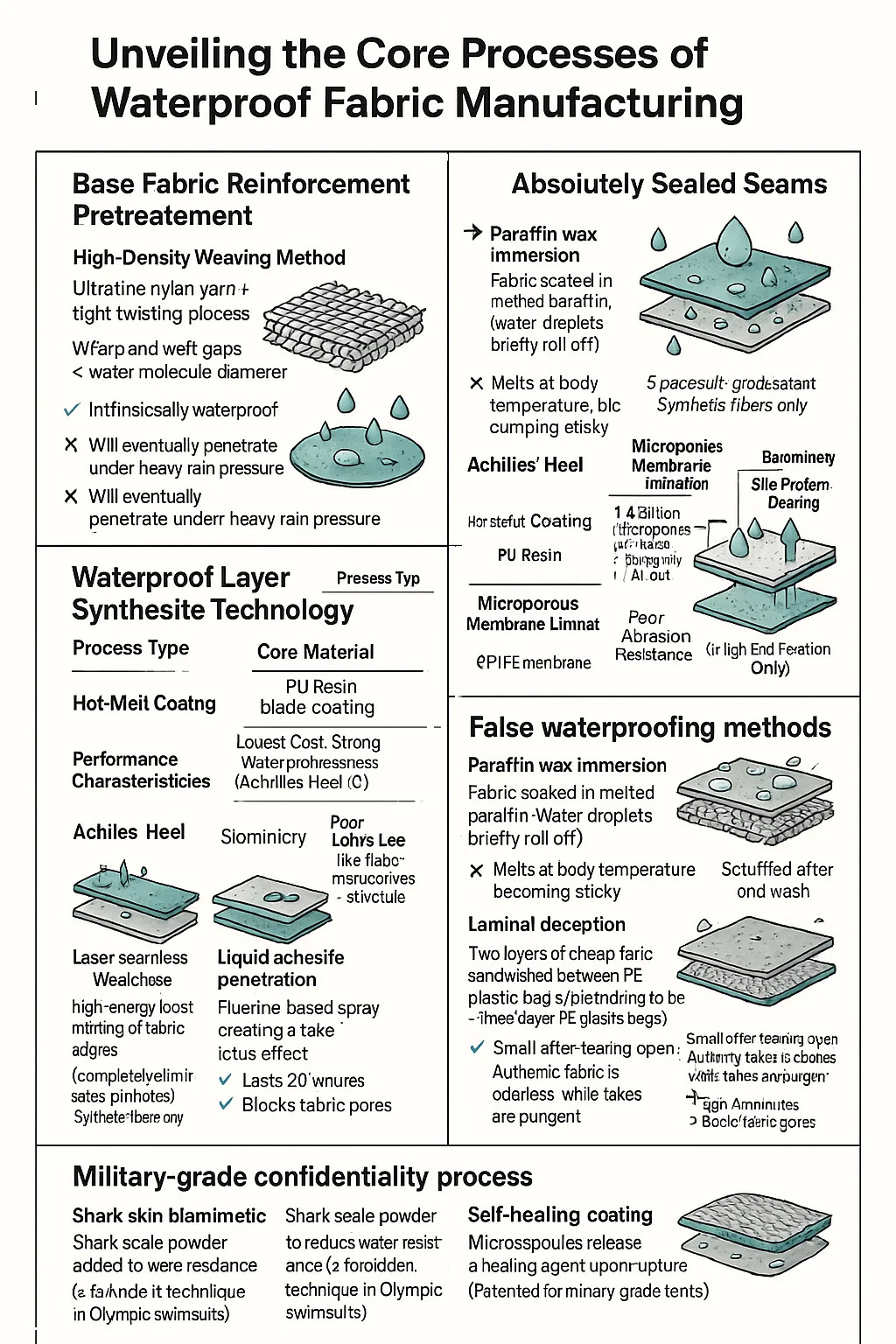

Unveiling the Core Processes of Waterproof Fabric Manufacturing

Content

1. Base Fabric Reinforcement Pretreatment

High-Density Weaving Method: Ultrafine nylon yarn + tight twisting process, warp and weft gaps < water molecule diameter (0.4nm)

** Intrinsically waterproof

** Will eventually penetrate under heavy rain pressure

** Will eventually penetrate under heavy rain pressure

**Fiber Hydrophobic Modification: Fluorocarbon high-pressure padding (C6/C8 formula) forms a nano-scale water-repellent layer on the fiber surface

** Durable

** Environmentally Controversial (Permanent Chemical)

2. Waterproof Layer Synthesis Technology

| Process Type | Core Material | Performance Traits | Critical Vulnerabilities |

|---|---|---|---|

| Hot-Melt Coating | Polyurethane (PU) Resin | • Lowest cost• Extreme water pressure resistance | • Zero breathability (suffocating like plastic sheeting) |

| Microporous Membrane Lamination | Expanded PTFE (ePTFE) Film | • 1.4 billion pores/cm² (blocks water/passes vapor)• Body-temperature regulation | • Oil contamination permanently clogs pores• Delaminates in humid heat |

| Biomimetic Fabrication | Silkworm Sericin Coating | • Self-cleaning lotus effect• UV-resistant molecular structure | • Fragile abrasion resistance (luxury fashion only)• Degrades in saltwater |

| Hybrid Nanoweave | Graphene-Enhanced Polyamide | • Electricity-conductive heating• Adaptive pore sizing | • $1,000+/sq.m production cost• Requires specialized care |

3. Absolutely Sealed Seams

Laser Seamless Weakness: High-energy laser melting of fabric edges (completely eliminates pinholes) ** Spacesuit-grade sealant ** Synthetic fibers only

Hot-pressed adhesive strip reinforcement: Waterproof tape applied to seams (temperature, pressure, and duration controlled) ** Standard outdoor gear ** Debonding after aging

Liquid adhesive penetration: Seams saturated with silicone resin (filling all pores) ** Stiff feel ** Debonding after five washes

4. False waterproofing methods

Paraffin wax immersion: Fabric soaked in melted paraffin (water droplets briefly roll off) ** Melts at body temperature, becoming sticky ** Scuffed after one wash

Laminar deception: Two layers of cheap fabric sandwiched between PE plastic bags (pretending to be three-layer PE plastic bags) ** Smell after tearing open: Authentic fabric is odorless, while fakes are pungent

Water repellent camouflage: Fluorine-based spray applied to create a fake lotus effect ** Lasts 20 minutes ** Blocks fabric pores

5. Military-grade confidentiality process

Shark skin biomimetic: Shark scale powder is added to reduce water resistance (a forbidden technique in Olympic swimsuits)

Self-healing coating: Microcapsules release a healing agent upon rupture (patented for military-grade tents)

Smart responsive membrane: Pores automatically shrink with increasing humidity (pore size <0.2μm during heavy rain)

English

English

PREV

PREV