Explore TN/C polyester/nylon/cotton series fabrics--Wuxi Boyibo Textile Finishing Co., Ltd.

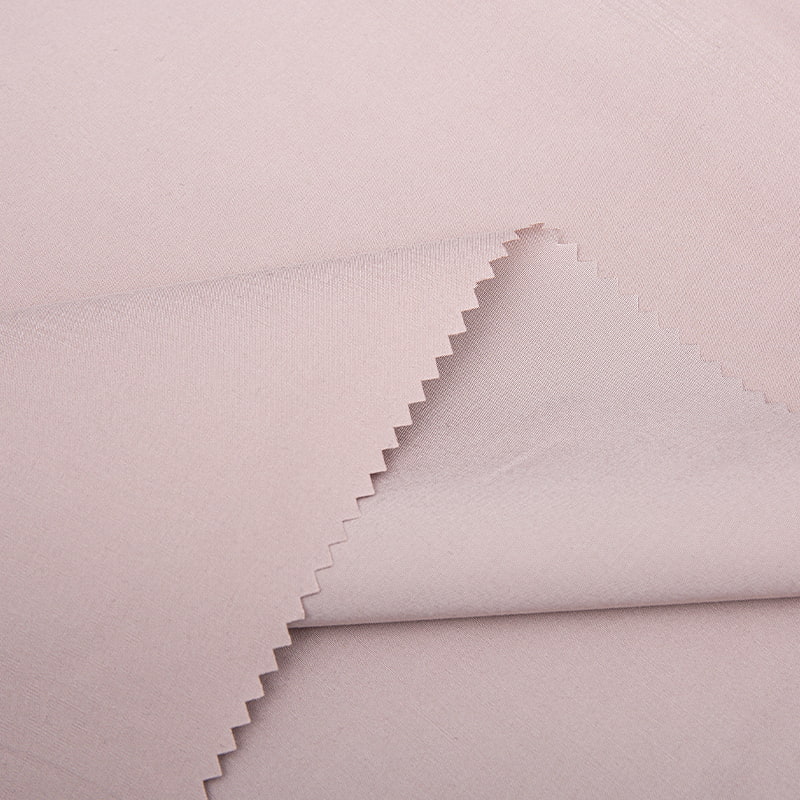

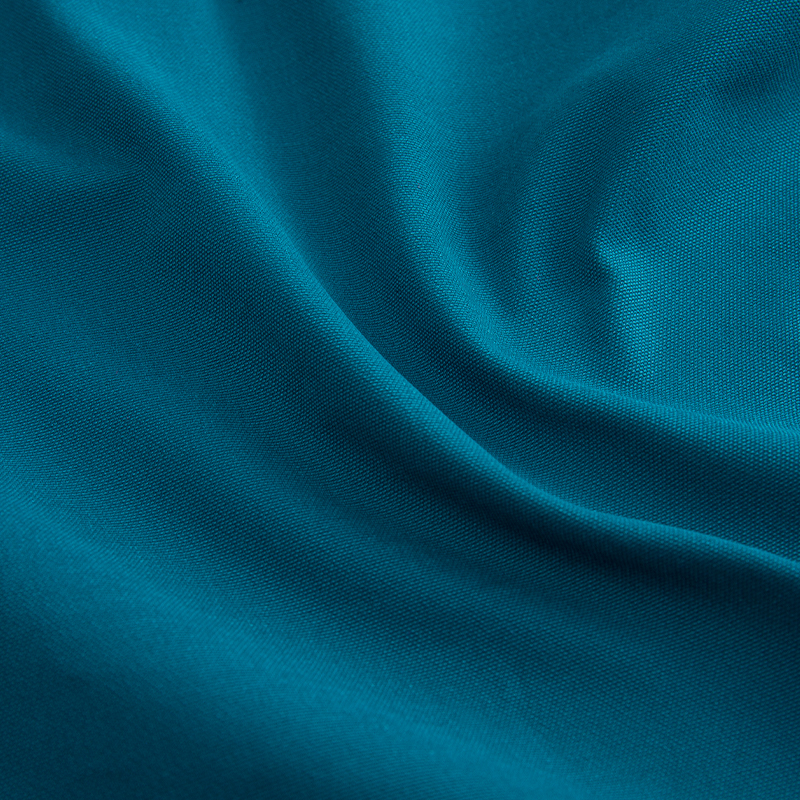

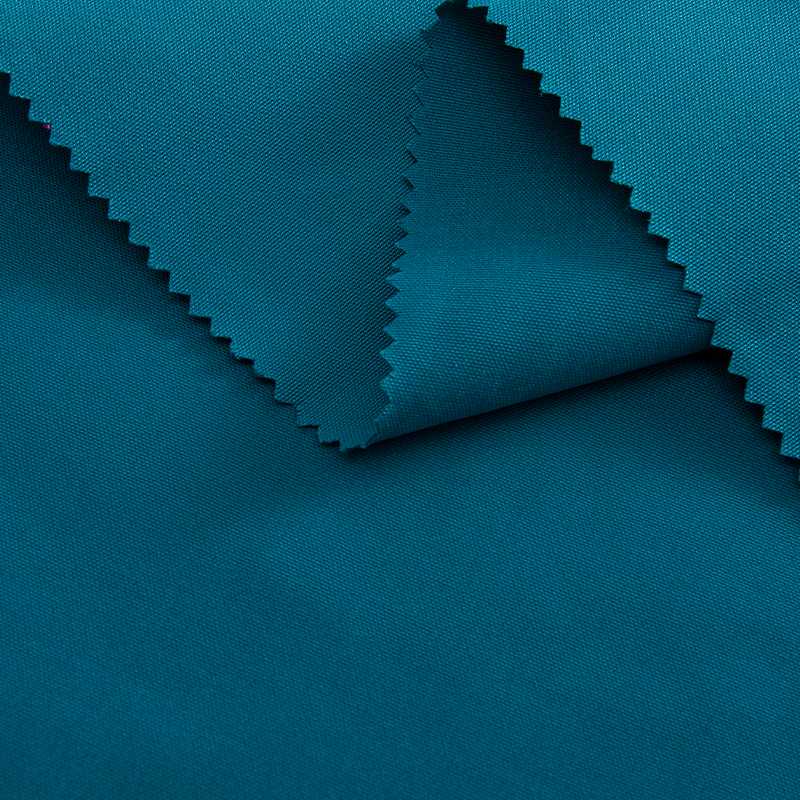

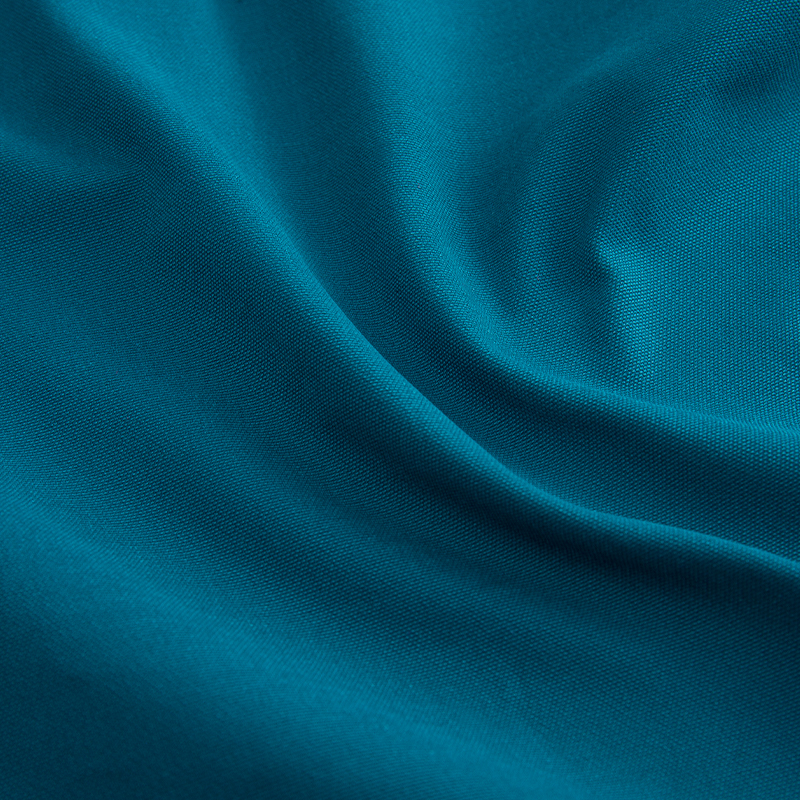

In the textile industry, TN/C polyester/nylon/cotton series fabrics are becoming a popular choice for functional textiles due to their unique blending properties. This fabric combines the durability of polyester, the elasticity of nylon and the comfort of cotton, providing strong support for various applications. As an industry-leading post-processing expert, Wuxi Boyibo Textile Finishing Co., Ltd. focuses on providing customized solutions for customers and ensures that fabrics meet excellent standards in energy saving, environmental protection, safety and high added value through continuous innovation and advanced equipment.

1. What is the core composition of TN/C polyester/nylon/cotton series fabric? How does it reflect the advantages of fiber fusion?

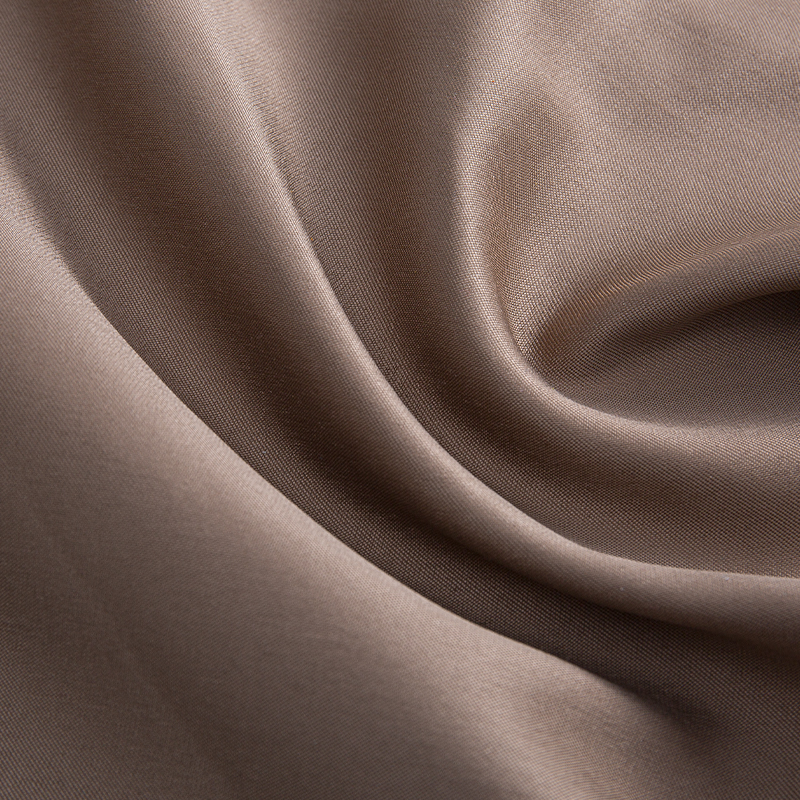

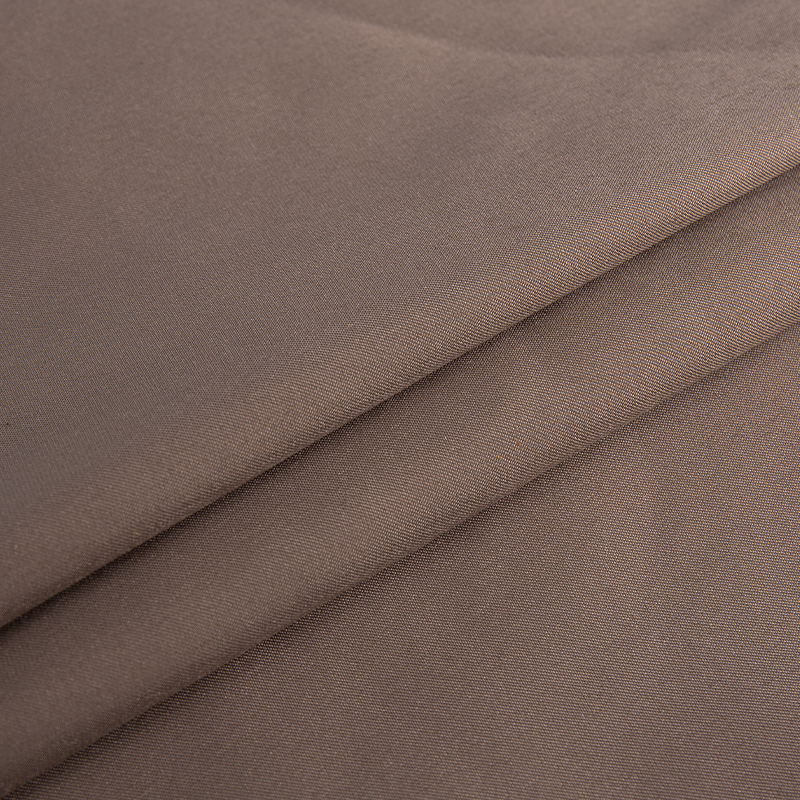

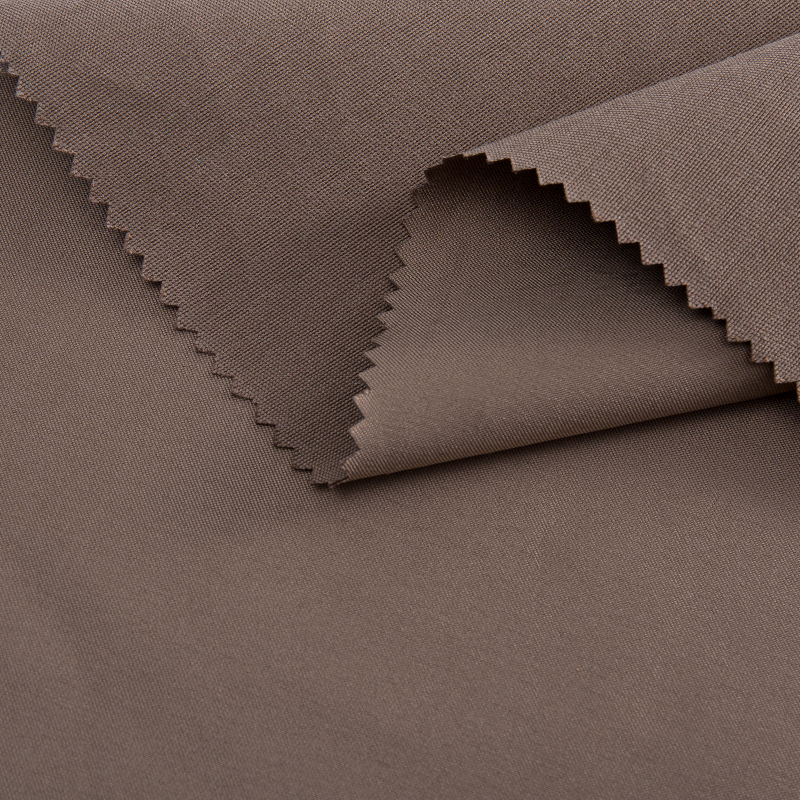

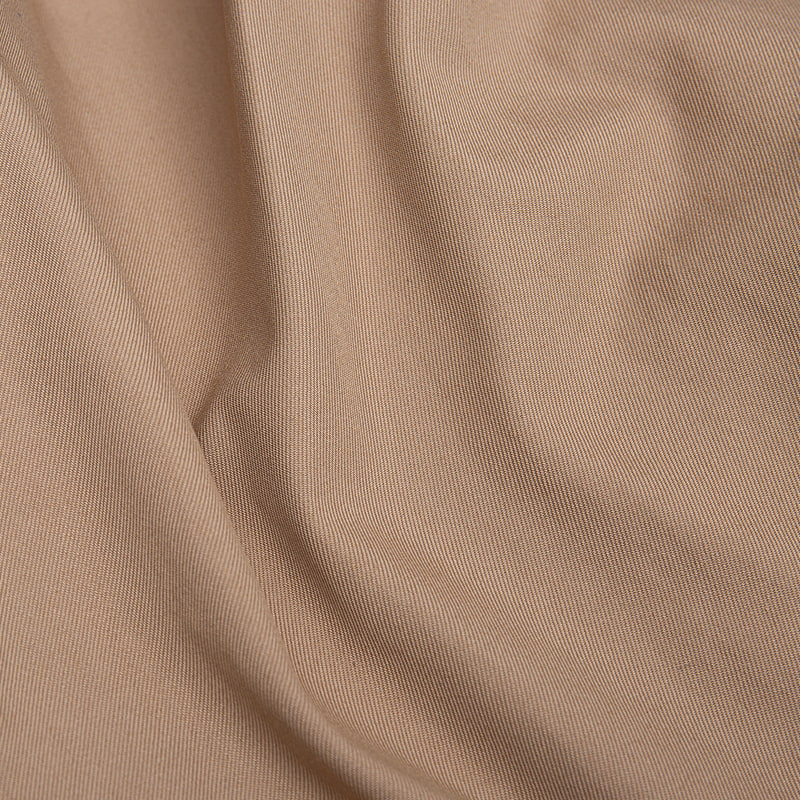

TN/C series fabrics are a multi-component fiber blend, in which polyester (polyester fiber) contributes high strength and wrinkle resistance, nylon (polyamide fiber) provides excellent elasticity and abrasion resistance, and cotton fiber ensures moisture absorption, breathability and skin-friendly comfort. This combination is not a simple superposition, but a synergistic effect created through scientific ratio design - for example, polyester and nylon make up for the wrinkle defect of cotton, and the natural properties of cotton neutralize the stiffness of synthetic fibers, ultimately forming a balanced "multifunctional fabric". When Wuxi Boyibo Textile Finishing Co., Ltd. takes over this type of fabric, it will carry out customized post-processing according to the specific needs of customers, using its deep processing technology to optimize the bonding degree between fibers to ensure the maximum mixing advantage.

2. What are the unique functional properties of TN/C fabrics? How does Wuxi Boyibo's post-processing further enhance these properties?

The uniqueness of this fabric lies in its versatility: it not only has mechanical strength that is wear-resistant and tear-resistant, but also has good breathability and moisture wicking capabilities, while being easy to care for and quick to dry. This makes TN/C fabrics popular in outdoor sportswear, workwear or home textile products because it can adapt to changing environments and provide all-weather comfort. The core advantage of Wuxi Boyibo Textile Finishing Co., Ltd. lies in the deep exploration of these characteristics through post-processing technology. The company has introduced advanced automated equipment from Germany and Italy, such as efficient dyeing machines and finishing systems, to treat TN/C fabrics in an environmentally friendly way. For example, the use of low-energy cold dyeing technology or nano-level coating can improve the waterproof and anti-fouling properties of the fabric while maintaining its soft feel. More importantly, Wuxi Boyibo emphasizes the principles of energy conservation and environmental protection. All treatment processes meet safety standards and reduce chemical residues, ensuring that the fabric is not only powerful but also has sustainable high added value.

3. What specific application scenarios are TN/C polyester/nylon/cotton fabrics suitable for? How does Wuxi Boyibo meet diverse needs through customized solutions?

The wide application of this hybrid fabric is due to its flexible design potential - it can be used for high-performance clothing (such as mountaineering clothes or uniforms), home textiles (such as sofa covers or bedding), and even extends to the industrial field (such as protective materials). The key lies in the targeted adjustment of post-treatment: for example, in sportswear, the fabric needs to enhance the moisture absorption and perspiration function; while in home textile products, more attention is paid to antibacterial and deodorizing properties. Wuxi Boyibo Textile Finishing Co., Ltd. is customer-oriented and provides customized solutions for the entire chain. The company not only performs basic finishing such as shaping or softening, but also develops special technologies such as flame retardant treatment or UV-resistant coating through deep processing research and development. Combined with its imported international equipment, Wuxi Boyibo can respond quickly to market changes and ensure that each batch of fabrics meets the high added value requirements of specific scenarios, such as creating low-carbon footprint products for environmentally friendly brands, or providing processing services that meet international standards for safety-sensitive industries.

4. What is the key impact of post-processing technology on the quality and added value of TN/C fabrics? How does Wuxi Boyibo's advanced equipment support this process?

Post-processing is a decisive link in the life cycle of TN/C fabrics, which can significantly improve the durability, appearance texture and functional added value of fabrics. The company continues to invest in research and development, and the automated equipment introduced from Europe (such as intelligent finishing lines and energy-saving drying systems) ensures the efficiency and consistency of the processing process. These equipment not only reduce energy and resource consumption, but also implement environmental protection concepts through closed-loop water circulation and low-emission technology. At the same time, Wuxi Boyibo's safety management system ensures risk-free operation, allowing TN/C fabrics to achieve high added value while meeting the green certification standards of the global market. This approach of integrating new technologies allows fabrics to leap from "ordinary blends" to "smart textiles", such as giving them temperature regulation or smart sensing functions through finishing.

5. How does Wuxi Boyibo promote innovation in TN/C fabrics in product research and development? How are its five major standards reflected in actual services?

Innovation is the core driving force for the development of TN/C fabrics. Wuxi Boyibo Textile Finishing Co., Ltd. continues to expand the boundaries of fabrics through independent research and development and deep processing cooperation. The company not only optimizes existing processes, but also explores cutting-edge technologies such as bio-based finishing agents or recyclable treatments to ensure that fabrics remain ahead in functionality, comfort and sustainability. Wuxi Boyibo's five major standards - energy saving, low consumption, environmental protection, safety and high added value - are the cornerstones of its services. In actual operation, this is manifested as: low-energy production through automated equipment; reduced water and chemical consumption to reduce environmental impact; strict safety protocols to prevent occupational hazards; and finally, delivering high-value-added products with market competitiveness to customers. For example, for TN/C fabrics, the company can develop customized finishing solutions to add antibacterial or antistatic properties while maintaining the original advantages, thereby enhancing the premium ability of the end product. This end-to-end service model not only enhances the practicality of the fabric, but also reflects the responsibility and foresight of Wuxi Boyibo as an industry partner.

TN/C polyester/nylon/cotton series fabrics represent the innovative integration of the textile industry, and the professional post-processing technology of Wuxi Boyibo Textile Finishing Co., Ltd. has injected vitality into it. Through customized solutions, advanced equipment and continuous research and development, the company ensures that every meter of fabric carries the promise of energy saving, environmental protection and high added value. For industry partners, choosing Wuxi Boyibo is not only choosing a service provider, but also embracing a sustainable development future driven by innovation.

English

English

2024-12-09

2024-12-09