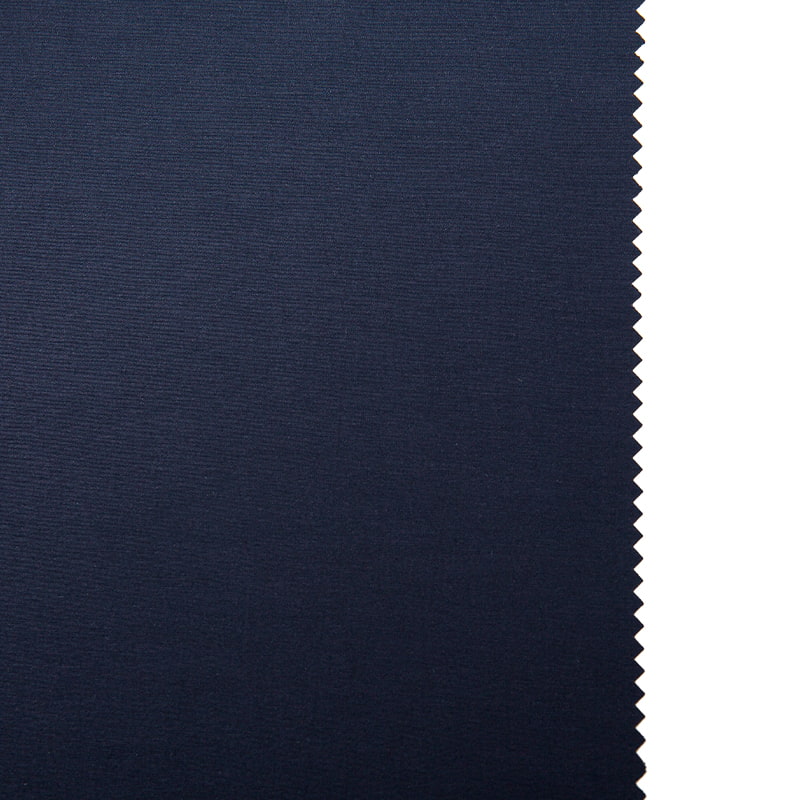

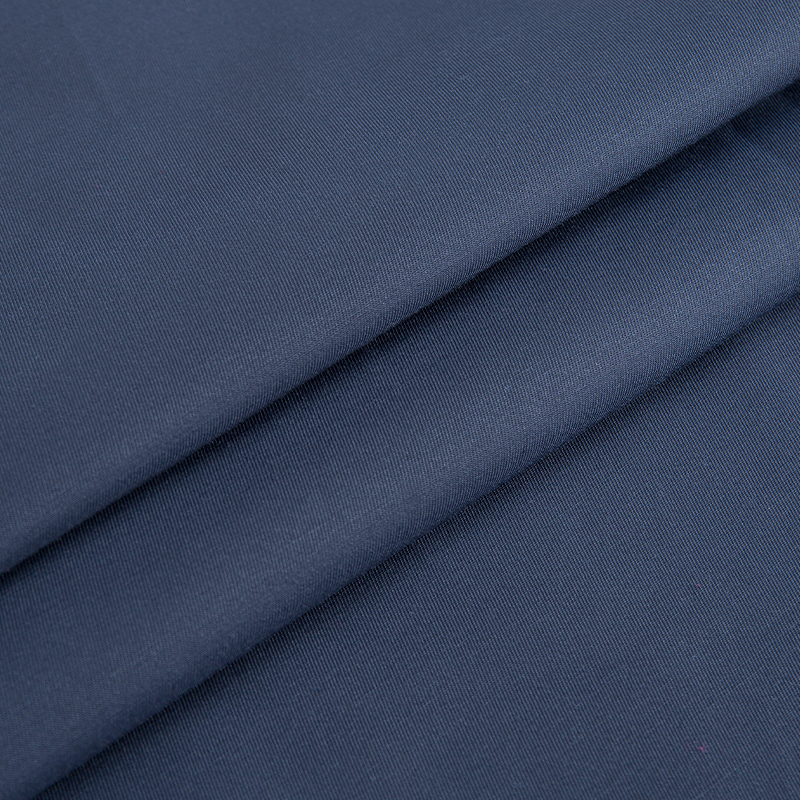

Deep decoding of T/C polyester/cotton series fabrics: How does Boyibo Textile unleash the potential of blending?

Q1: How to balance the core value of polyester-cotton blends?

A1: T/C fabrics meet multifunctional wearing needs by scientifically matching the strength of polyester and the comfort of cotton. With its grey fabric supply chain resources, Boyibo Textile can accurately customize differentiated blended substrates for scene requirements such as wear resistance of workwear and breathability of casual wear, so that the performance of the fabric is highly consistent with the end use.

Q2: How does the blending ratio affect the finishing process?

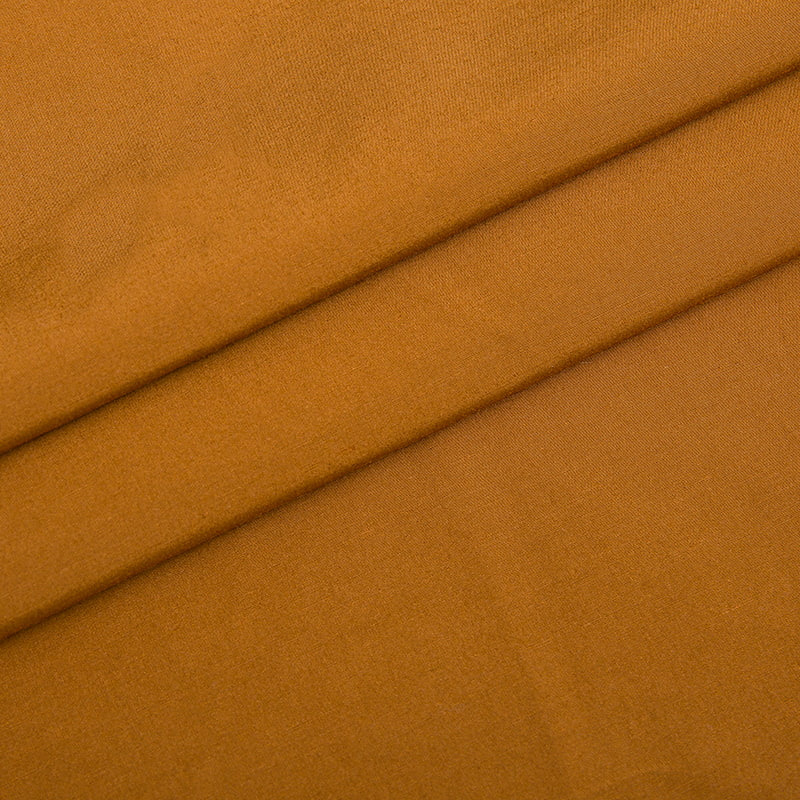

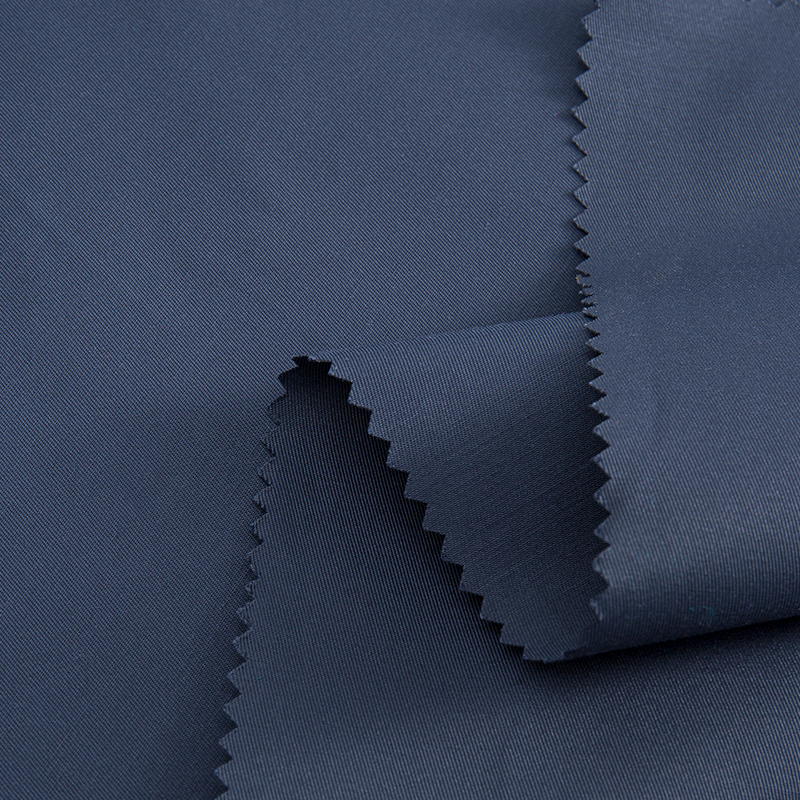

A2: The tear resistance advantage of high polyester content fabrics needs to be compensated by hydrophilic additives to make up for the moisture absorption defect, while high cotton ratio fabrics require special shrinkage prevention treatment. Boyibo cooperates with cooperative additive factories to develop customized solutions, such as using low formaldehyde resin to improve the dimensional stability of cotton fibers, and using penetrating softeners to solve the stiffness of high polyester fabrics, achieving dual optimization of performance and feel.

Q3: How does finishing technology give fabrics high added value?

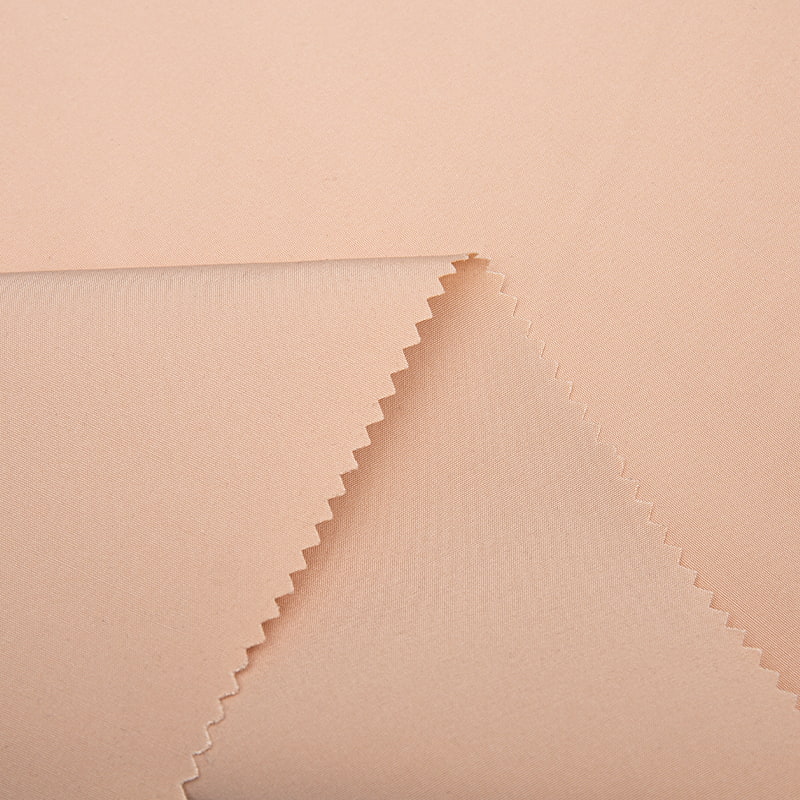

A3: Boyibo integrates the cutting-edge R&D resources of auxiliary manufacturers to give conventional polyester-cotton special functions. Its heat setting process parameter library can ensure the washability of fabrics, while the composite functional finishing technology can simultaneously superimpose antibacterial, antistatic and other properties. In response to the environmental protection trend, the company uses fluorine-free water repellent and low bath ratio dyeing process to meet ecological requirements while ensuring protective effectiveness.

Q4: How to overcome the difference in double fiber dyeing?

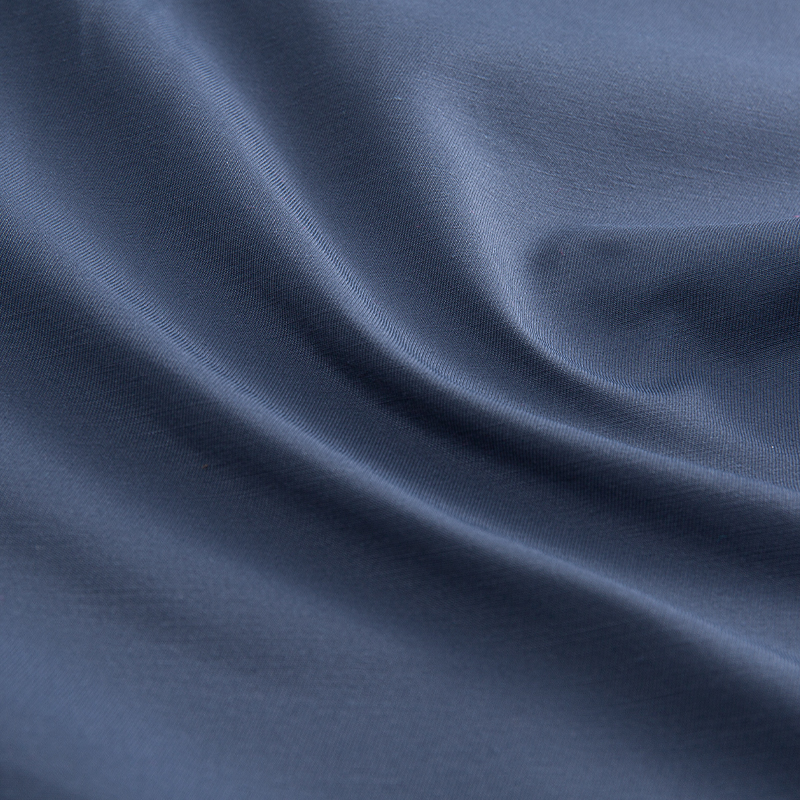

A4: Boyibo solves the problem of synchronization of polyester-cotton dyeing through the dye compatibility system. The combination of selected high-penetration disperse dyes and cotton active dyes, combined with the staged temperature control process, effectively avoids the phenomenon of color flower. The composite color fixing agent developed in cooperation not only improves color fastness, but also maintains the original softness of the fabric, avoiding the problem of hardening caused by traditional color fixing.

Q5: How does supply chain collaboration ensure quality?

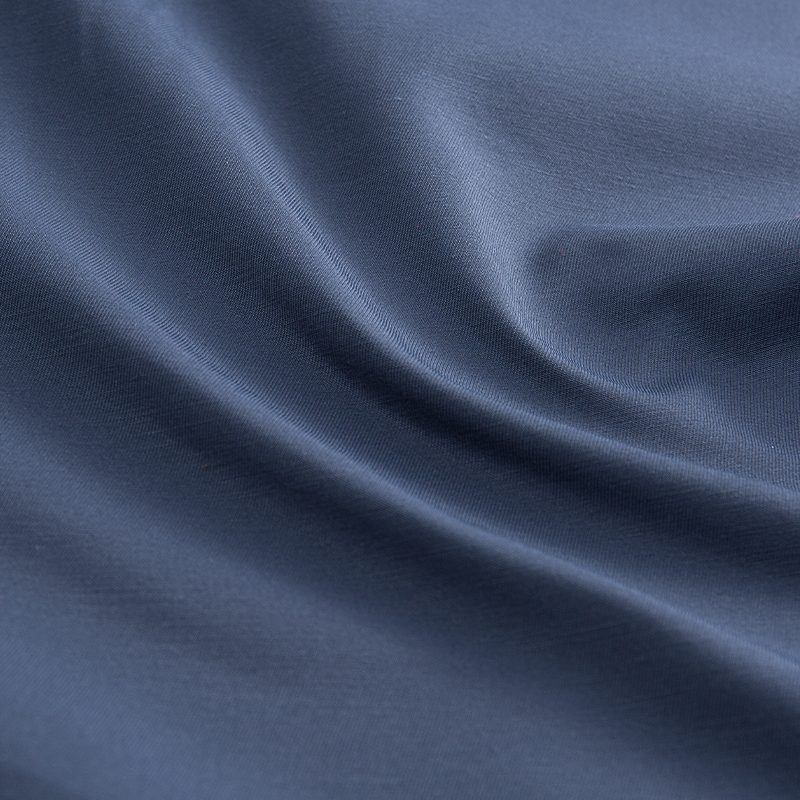

A5: From the selection of grey cloth raw materials to the batch control of dyeing and chemical materials, Boyibo relies on a deeply cooperative manufacturing network to establish full-chain quality control. Its grey fabric suppliers can avoid potential defects such as yarn knots and horizontal bars during the weaving stage, while the direct supply system of dyes and chemicals ensures the stability of the performance of auxiliaries. This vertical integration model enables customers to obtain standardized quality output even in urgent orders.

Q6: How does Boyibo break through homogeneous competition?

A6: The company upgrades the role of dyeing factories to fabric solution designers. By mobilizing the three-dimensional resource network of dyes, chemicals, auxiliaries and grey fabrics, it provides customers with full-process technical collaboration from fiber ratio to functional customization. This capability based on deep integration of the supply chain enables customers to obtain performance premiums beyond conventional supply chains while avoiding quality risks.

English

English

2024-12-09

2024-12-09